Welcome back to part 2 of the importance of safety showers and eye/face wash system where we will summarize the role of thermostatic mixing vales (TMV) and how it fits into the safety showers and eye/face wash stations systems. Here’s a link of the previous post if you are new here. A quick recap: businesses or facilities that handles and stores hazardous substance are required to provide a safety shower, eye/face wash systems and water for hand-washing in the facility as per NZ’s Health and Safety at Work (Hazardous Substance) Regulations 2017.

The emergency shower is an engineered device to dispense flushing fluids to flow over the entire body while the eye/face wash systems is designed to spray-flush and rinse the eyes of foreign materials. The American National Standard (ANSI) released the following standards (ANSI Z358.1) where it establishes the minimum design, performance, installation, maintenance and usage properties for the “Emergency Eyewash and Shower Equipment.” The standards requires that the emergency safety eyewash and shower systems’ installed location be located within 10 seconds of hazard on the same level without accessibility obstructions with clear and visible signage with tepid water delivered, and all employees are trained in its proper usage. The systems must also be inspected and maintained accordingly.

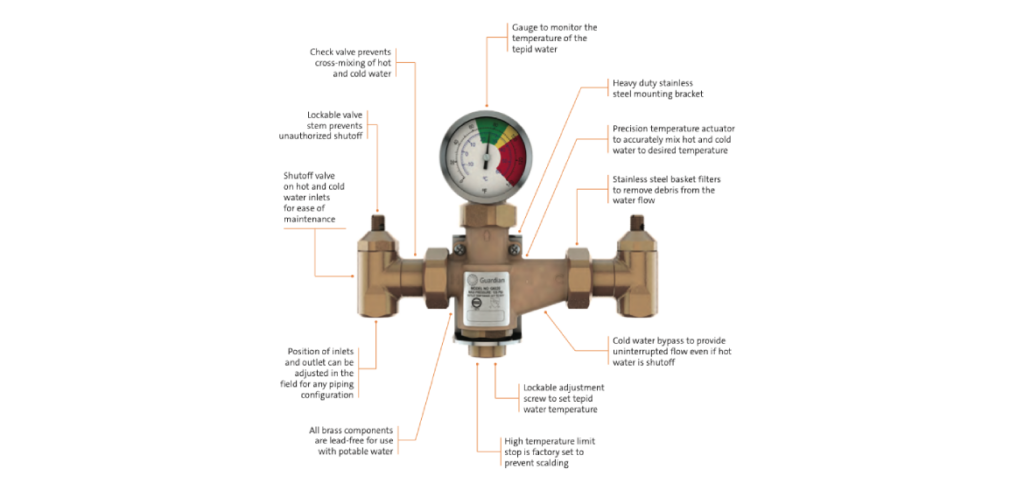

For the emergency safety showers and eye/face wash systems to deliver high volumes of water to flush away hazardous chemicals when a spill or accident has occurred at a safe temperature, the thermostatic mixing valves (TMV) is an excellent device fittings connected directly to the water supply feed to facilitate the blending of hot and cold water to a desired pre-set for a consistent temperature to deliver regulated “tepid” flushing water around the temperature range of 60°F (16°C) and 100°F (38°C) which offers protection from scalding injuries due to its valves reliability. Another benefit in investing in a TMV for a facilities safety shower and eye/face wash systems is the prevention of the Legionellosis from the gram-negative Legionella pneumophilla bacterium, which may thrive in a buildings’ water system at temperatures of 20°C to 50°C and water not used too often.

What the TMV looks like:

A quick checklist reference can be found here provided by Guardian Equipment. Rifft Safety supplies the following TMV units: G6040 (189L) for combination units and the G6020 (49L) for eye/face washes.

Where extreme environments may result in freezing temperatures, there are options for a heat-traced safety stations where it’s regulated with a thermostat unit featuring a self-limiting heat-tracing cable wrapped around the internal piping system. There is also the option to install the dual-purpose mounted deck eyewash/drench hose unit which can be either a fixed eyewash unit or as a drench hose rinse either eyes, face or body. In lieu of facilities that lacks continuous supply of potable water, there is also the portable self-contained eyewash/drench hose unit with a holding capacity of 56L available from Riff Safety.

If you have just discovered our page, hello and welcome. Feel free to say hi and give us a quick follow here.

Tags: worker facility, health and safety, safety shower, eye wash, first aid, lab safety, ANSI, Guardian Equipment, TMV, thermostatic mixing valve,